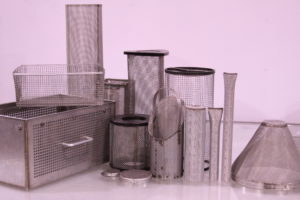

Custom Wire Cloth Filters & Filter Assembly Products

Custom Filtration Inc. supplies wire cloth filters and filter assemblies for a variety of applications and industries. We have the capabilities to manufacture custom wire cloth filters, fabricated screens, deep-draw strainers, and multi-contour filter elements. Working with wire cloth from 2″ mesh down to 2 micron mesh allows us to customize products for just about any application. Customers can also specify the weave type. We have plain, plain dutch, twilled and twilled dutch weaves. At our facility we offer custom slitting of wire cloth material from ½” up to 60″ widths and we have the ability to roll up to 1,000′ of material. Our in-house tooling and machining capabilities allow us to shorten our lead times and function as a specialty fabrication shop.

To learn more about the custom wire cloth filters and the materials we work with, please contact us or see the table below.

Custom Wire Cloth Products Specifications:

- Capabilities

Custom Wire Cloth Filters

Fabricated ScreensDeep Draw Strainers

Multi-Contour Filter Elements

- Industries Served

Agriculture/Machinery

Food and Beverage Processing

Fire Suppression

Chemical Processing

Mining OperationsHydraulic Components

Oil and Gas Processing

Casting/Foundries

Irrigation

Floor Maintenance

- Custom Slitting Of Wire Cloth Materials

Widths From 1/2″ up to 60″

Lengths Up To 1000′

- Weave Types

Plain Weave

Simplest, most commonly used. Warp, fill wires parallel and equidistant. Permits positive control of size of materials to be screened or filtered.

Plain Dutch Weave

Coarse mesh in the warp, fine mesh in the fill. Compact, strong, very fine openings, high particle retention. Used primarily as filter cloth.

Twilled Weave

Each fill wire passes alternately over and under 2 warp wires, staggered on successive warps. Used where fine mesh must carry a heavy load.Twilled Dutch Weave

Coarse mesh in warp, fine mesh in the fill. Each fill wire passed over and under 2 warp wires.

- Types of Material Used

Stainless Steel Alloys

The most commonly used alloys. Show long life under corrosive and relatively high temperature conditions. Stainless steel alloys show fair abrasion resistance. Type 304 and type 316 are the principle alloys used for wire cloth.Copper

Low tensile strength, however, it resists sulfuric acid. Copper alloys are often used for wire mesh.Brass

(Cu 80% Zn 20%) stands up much better under impact than copper.Bronze

(Cu 90% Zn 10%) Higher copper alloy means better corrosion resistance than brass.Phosphor Bronze

Contains 4% to 9% tin and a small amount of phosphorous. It is often used in very small wire diameters.Aluminum

Very light weight and strong. Resists nitric and sulfuric acid under normal temperatures. Has poor abrasion resistance and should not be used in high temperature applications.Monel

High nickel copper alloy. Stronger than steel and extremely corrosion resistant. Better under high temperature conditions.Inconel

High nickel chromium alloy. Good for corrosion resistance and excellent for high temperatures. High impact resistance.Plain Steel (carbon steel)

When corrosion or abrasion resistance is not important, steel can be used. The most economical metal for wire cloth. Often painted or coated (galvanized)

- Wire Cloth Terminology

Mesh

Number of openings per linear inch measured from center to center of parallel wires.Square Mesh

Mesh count identical in both directions.

Rectangular Mesh (off count)

Mesh count greater in one direction than in the other.Space

Actual open space (size of opening).Warp Wire

Wire running length of cloth.

Shute (fill) Wire

Wire running across width of cloth.Gauge

Measurement of wire diameter (best expressed in decimal sizes).Crimp

Indentations in warp and fill wires which lock wires in position.

Double Crimp

Equal crimp in both warp and fill wires.Intermediate Crimp

Extra crimps between intersections, usually found in coarse mesh cloth to add rigidity & accuracy of mesh.Selvage

Finished woven edge of wire cloth formed by loops of fill wire.

- Production Volume

Specialty Production Shop

Prototype

Low Volume

Small RunHigh Volume

Large Run

Long Run

Large Scale Production Volume Run