Portfolio

Slit Wire Cloth

A customer from the plumbing industry approached Custom Filtration Inc. to slit 10,000 linear feet of brass wire cloth. Using a custom built slitter, the mesh which had a wire diameter of .0065″ was slit to the customer specified dimensions. The final brass coils were 200′ in length and 2.9″ wide. We were able to maintain tightest tolerances of ±.010″ throughout the entire silting process.After checking and recording the brass wire cloth’s slit width, we delivered the completed cloth to the client’s Philadelphia, PA location.

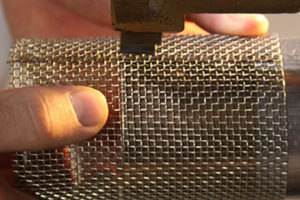

Welded Cylinder

Custom Filtration Inc. was approached by a customer from the floor maintenance industry to slit and weld 1,200 stainless steel cylindrical screens. Using a custom built slitter, we first slit the screen to measure 4.875″ wide. Then, we cut the parts down so they measured 8.6″ long. Lastly, we resistance welded the screens into cylinders that were 4.875″ long and had a diameter of 2.625″.Throughout the entire process, we were able to hold tightest tolerances of ±.025″. After a thorough inspection, we shipped the 316 stainless steel screens to the customer’s Los Angeles, CA location

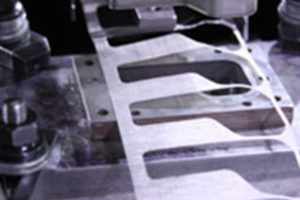

Stamped Discs and Blanks

Custom Filtration Inc. was approached by a client from the ATV industry to stamp 5,000 stainless steel mesh blanks. The blanks were to be used for oil pick-up during the manufacture of all-terrain vehicles.Using our own custom built machinery and dies, we slit and stamped the 304 stainless steel blanks. In order to guarantee a high-level of quality control, we inspected and recorded the blanks for burrs and other problems. The finished blanks, which measured 1.8″ long and 1.230″ wide, were then delivered to the client’s Minneapolis, MN location.

Molded PVC

A customer from the parts washing industry approached Custom Filtration Inc. to manufacture 2500 custom stainless steel strainers. We started by slitting wire mesh and mesh material for the strainers using a custom built slitter. We then die cut, rolled and resistance welded the components using our own custom made machinery. The strainer’s PVC thread and cap ends were then molded. We were able to hold tightest tolerances of ±.025″ throughout the entire manufacturing process.The finished custom fabricated 304 stainless steel strainers had an outside diameter of 2.885″, measured 4.565″ long, and were delivered to the client’s Houston, TX location.